Carbide da aka yi da siminti wani nau'in abu ne mai ƙarfi wanda ya ƙunshi ƙarfe mai ƙarfi da ƙarfe mai ɗaurewa, wanda aka samar da ƙarfe na foda kuma yana da tsayin daka da juriya. Saboda kyakkyawan aikinsa, ana amfani da simintin carbide sosai a cikin yankan, sassa masu jurewa, hako ma'adinai, hakowa na ƙasa, hakar mai, sassa na inji da sauran filayen.

Tsarin samar da simintin carbide ya haɗa da manyan matakai guda uku: shirye-shiryen cakuda, gyare-gyaren latsa da sintering. To mene ne tsari?

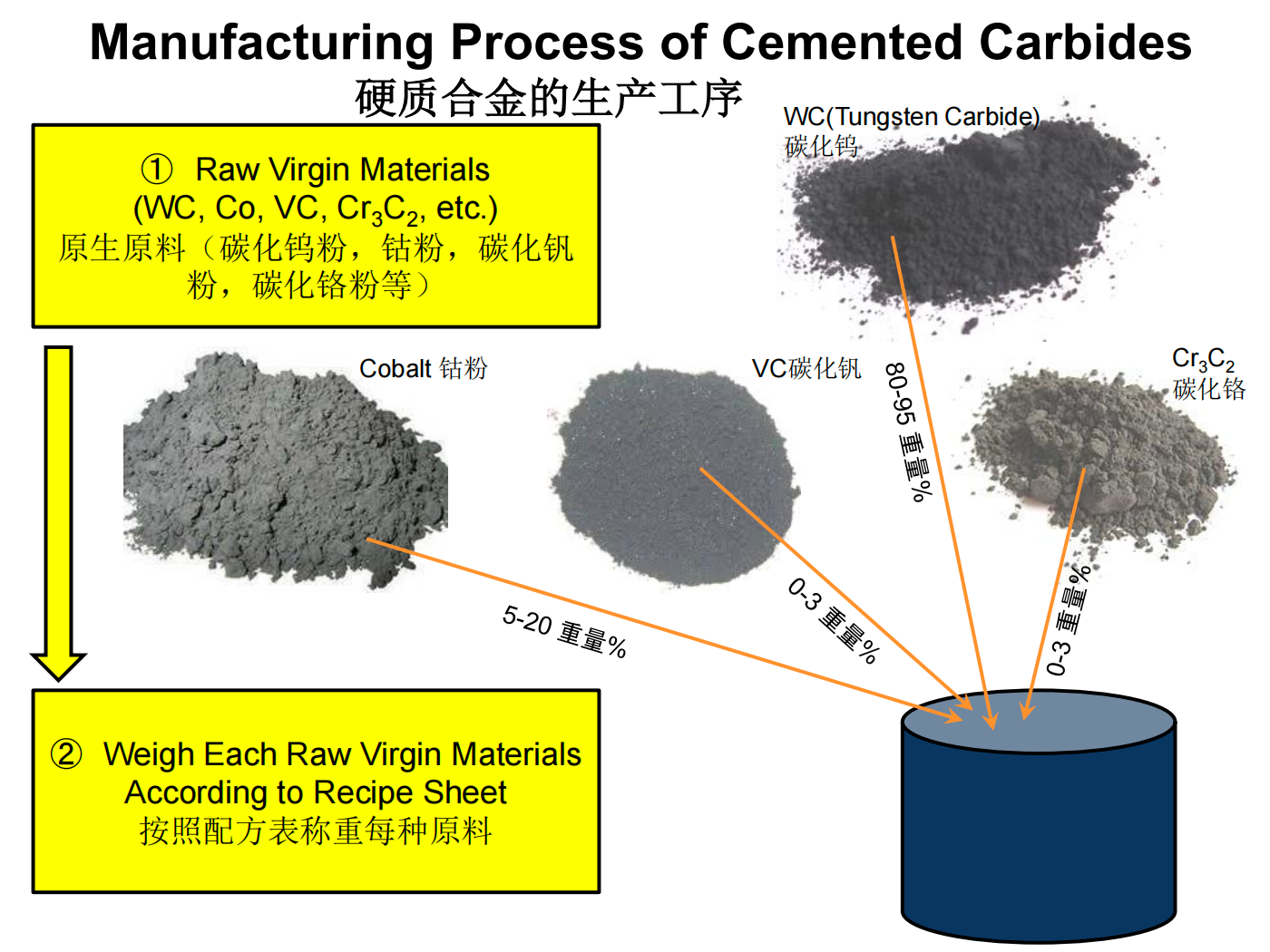

Tsarin batching da ka'ida

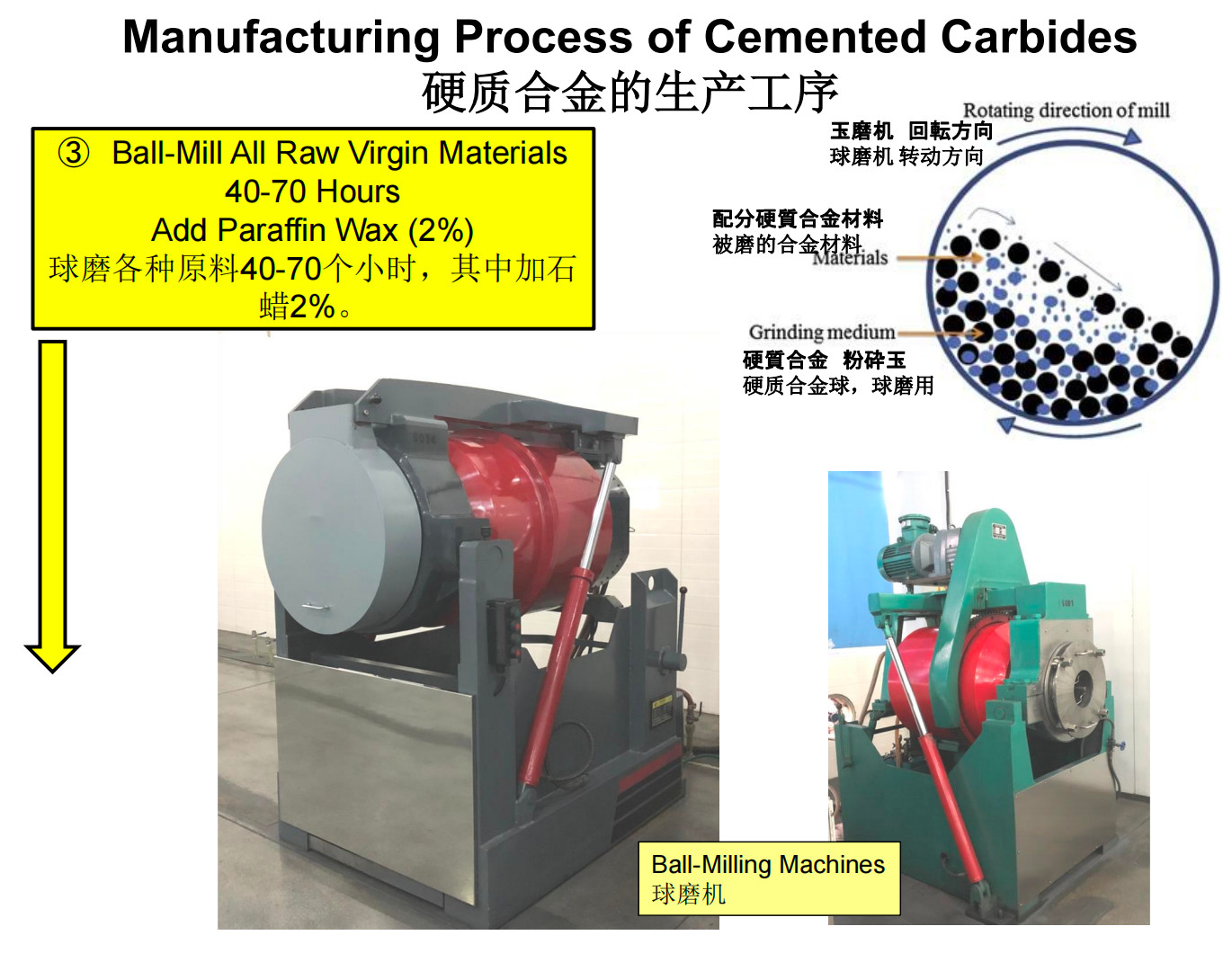

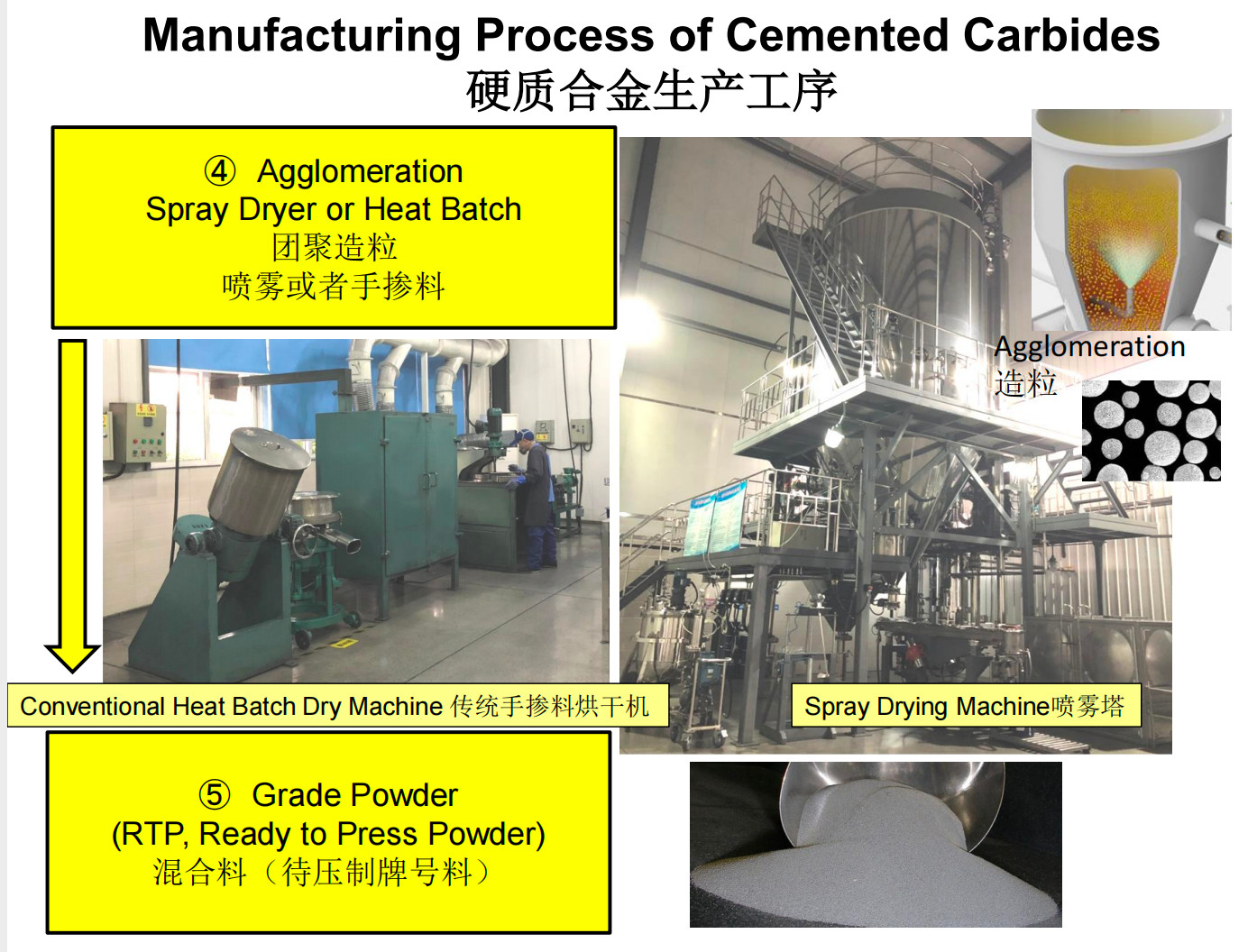

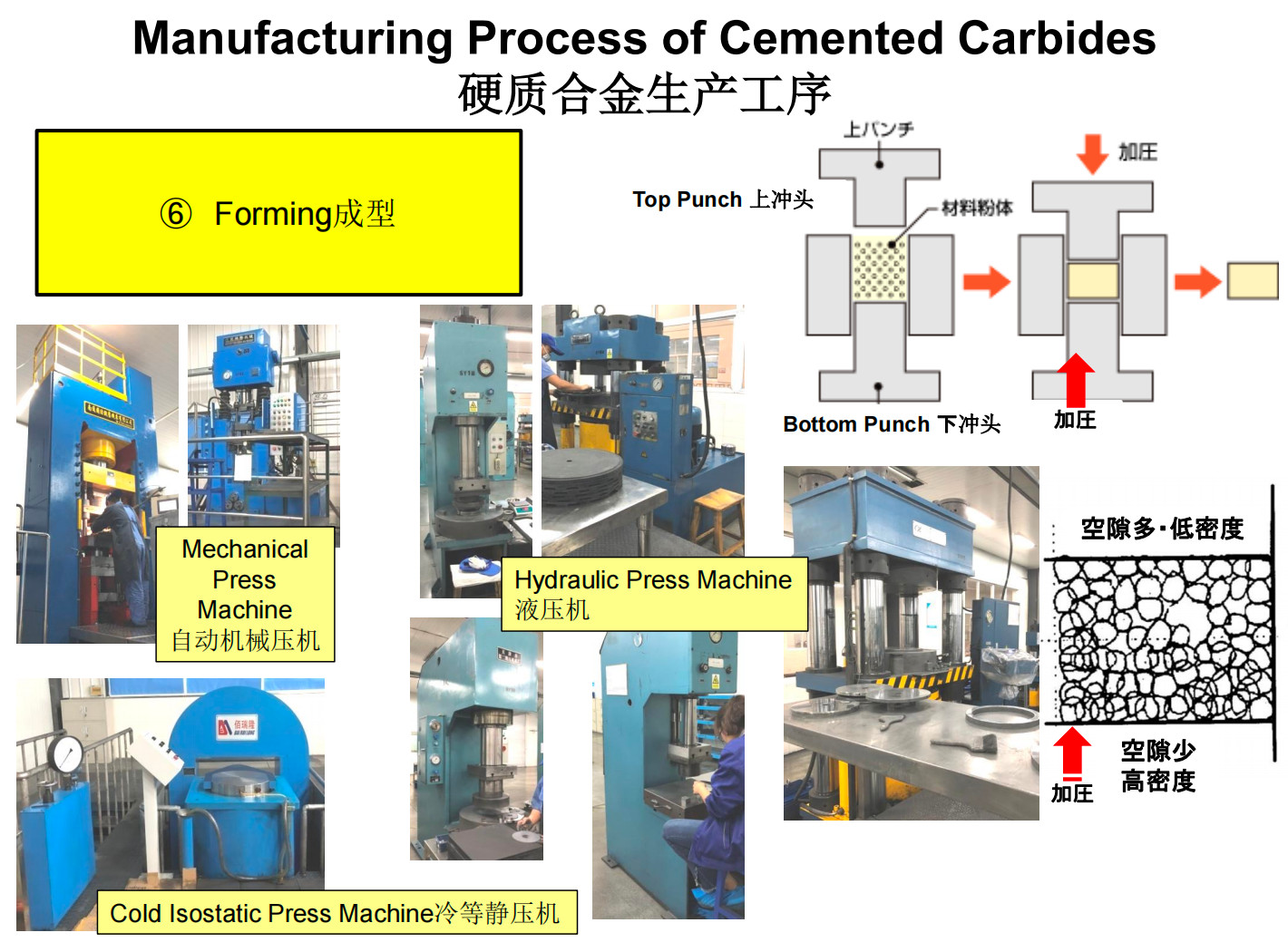

Yi la'akari da albarkatun da ake buƙata (tungsten carbide foda, cobalt foda, vanadium carbide foda, chromium carbide foda da karamin adadin Additives), Mix su bisa ga dabara tebur, saka su a cikin wani mirgina ball niƙa ko mahautsini zuwa niƙa daban-daban albarkatun kasa na 40-70 hours, ƙara 2% kakin zuma, tace da kuma ko'ina rarraba da albarkatun kasa, da kuma fesa da busassun buƙatun a cikin wani yanki na busassun buƙatun da kuma fesa busassun buƙatun. hadawa hannu da nunin jijjiga, Don saduwa da buƙatun latsawa da sintering. Bayan latsawa da ƙwanƙwasa, ana fitar da simintin carbide blanks kuma ana tattara su bayan ingantaccen dubawa.

Mixed sinadaran

Rigar niƙa

Shigar da manne, bushewa da granulation

Danna gyare-gyare

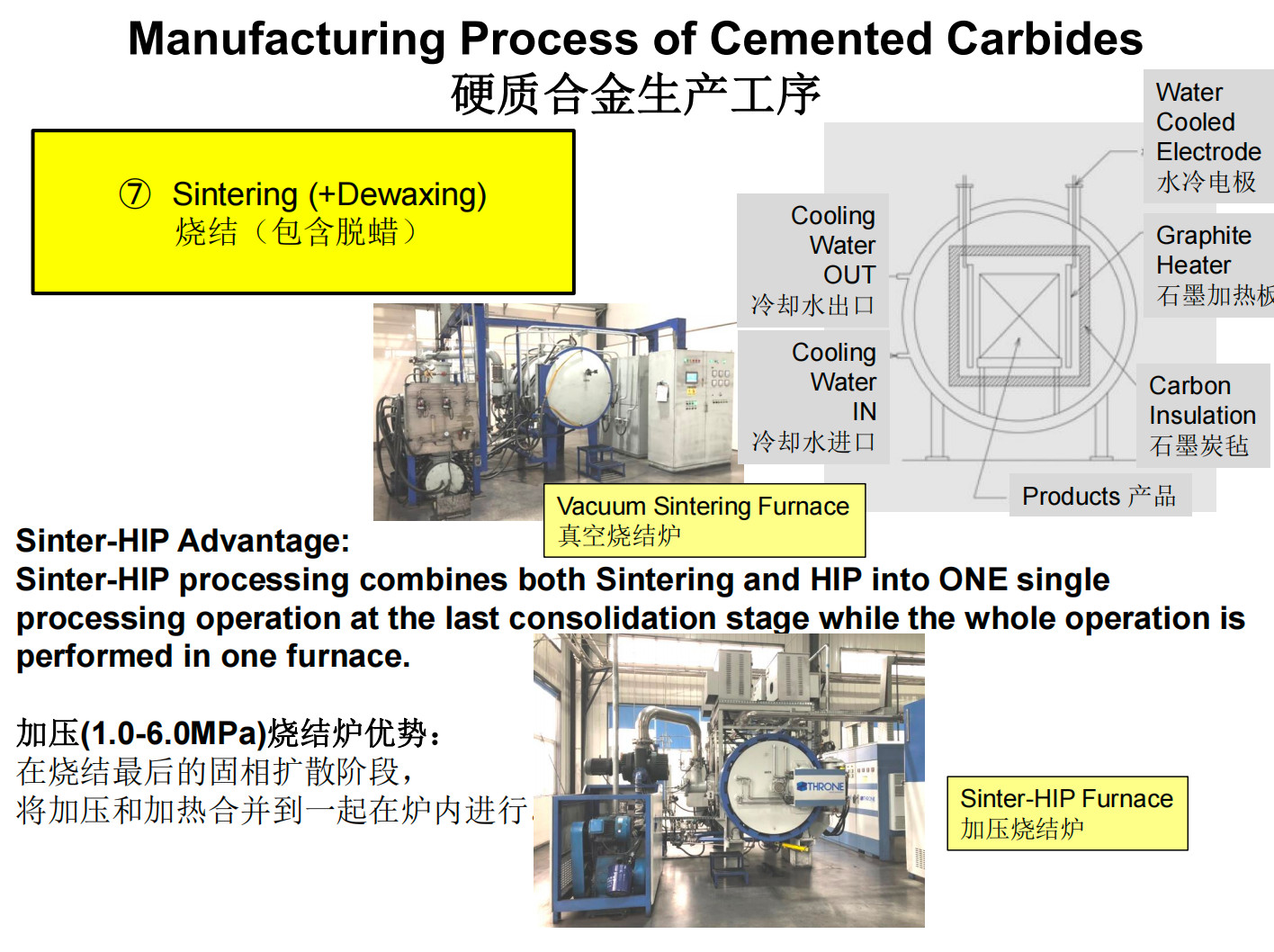

Sinter

Cemented carbide babu komai

Dubawa

Menene vacuum?

Matsakaicin irin wannan yanki ne mai matsananciyar iskar gas ya fi ƙanƙanta fiye da na yanayi. Masana kimiyyar lissafi sukan tattauna kyakkyawan sakamakon gwajin a cikin yanayin cikakken vacuum, wanda wani lokaci sukan kira vacuum ko sarari kyauta. Sa'an nan kuma a yi amfani da ɓarna mai ɓarna don wakiltar rashin cikawa a cikin dakin gwaje-gwaje ko a sararin samaniya. A gefe guda, a cikin aikin injiniya da aikace-aikacen jiki, muna nufin kowane sarari ƙasa da matsa lamba na yanayi.

Nau'in lahani / hatsarori a cikin samar da samfuran carbide da aka yi da siminti

Komawa ga tushen tushen, mafi yawan lahani / hatsarori na siminti na samar da carbide ana iya kasu kashi hudu:

Lalacewar ɓangaren (lokacin ETA ya bayyana, manyan ƙungiyoyin barbashi suna tasowa, faɗuwar foda)

Lalacewar sarrafawa (fashewar walda, fasa yankan waya, fasarar zafi)

Hatsarin muhalli (lalacewa, lahani na yazawa, da sauransu)

Hadarur injina (kamar gaggarumar karo, lalacewa, lalacewar gajiya, da sauransu)

Lokacin aikawa: Jul-27-2022