Kayayyaki

Cimined Tungsten Carbide Hannun Hannun Hannu Don Filin Mai Submersibe

Gabatarwar Samfur

Tungsten carbide sleeve aikace-aikace yana da faɗi, wanda shine na'ura don kare nau'in abubuwan da aka gyara.Yana cikin ainihin aikin kuma rawar da maƙasudin yanayin aikace-aikacen sa suna da kyakkyawar alaƙa.

Aikace-aikacen Valve, za a shigar da bushings a cikin tarkon bawul mai tushe, don rage zubar da bawul, don hatimi;aikace-aikacen ɗaukar hoto, yin amfani da daji don rage lalacewa tsakanin ɗamarar da wurin zama, guje wa rata tsakanin ramin da rami yana ƙaruwa da sauransu.

Tungsten carbide hannun riga samar da aiki na high-ƙarfi, iya jure dadewa nauyi, tare da high sinadaran kwanciyar hankali, alkali, barasa, ether, hydrocarbons, acid, mai, wanka, ruwa (ruwa ruwa), kuma ba shi da wani wari , mara guba, m, wadanda ba tsatsa halaye, ta yadu amfani a petrochemical masana'antu for Submerged Oil Pump, slurry famfo, ruwa famfo, Centrifugal famfo, da dai sauransu.

abũbuwan amfãni

1, 100% Danye:

Ana samar da bushes tare da kayan albarkatun ƙasa mai tsabta, wanda ke da halaye na tsawon rayuwar sabis da kwanciyar hankali.

2, Mashi:

Bushings ana sarrafa ta high-daidaici kayan aiki: CNC machining cibiyar, nika inji, milling inji, hakowa inji, a kwance milling inji, chamfering inji, Karfe Stamping, CNC sabon na'ura da dai sauransu

3, Akwai nau'ikan girma dabam:

Za mu iya samar da bearing bushings daban-daban masu girma dabam, cikakken molds da gajeren bayarwa lokaci.7-10 kwanaki don samfurori .20-25 aiki kwanaki domin taro productions.

4, Tabbacin inganci:

Unsurpassed Quality Standards.Our bushings hannayen riga bearings an tsara da kerarre bisa ga stringent ingancin matsayin da mulkin abu selection, machining, surface karewa, dubawa da kuma marufi.

Nunawa

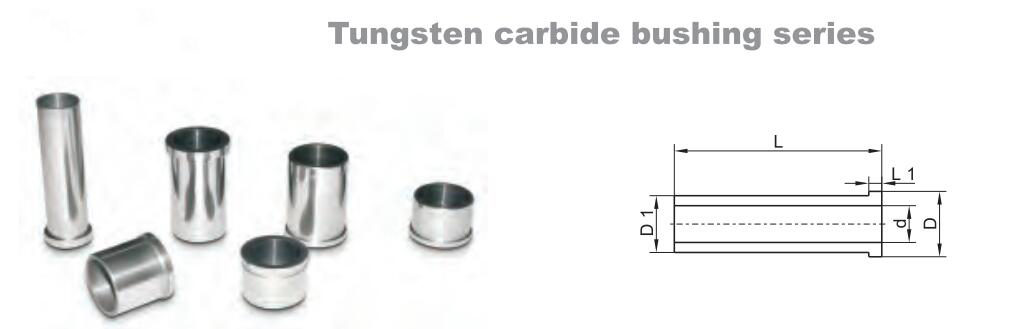

Zane daki-daki

Teburin kayan aiki

| Daraja | ISO | Ƙayyadaddun bayanai | Aikace-aikace na tungsten carbide | ||

| Yawan yawa | TRS | Tauri | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Wanda ya cancanci yin injin ƙarfe mai sanyi, baƙin ƙarfe simintin ƙarfe, ƙarfe mai jujjuyawa da ƙarfe na gami.Hakanan Ya cancanci yin aikin ƙarfe na yau da kullun. |

| YG06 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | Wanda ya cancanci yin aikin gamawa da na'ura mai ƙarancin ƙarewa don simintin ƙarfe, ƙarfe mara ƙarfe, gami da kayan da ba a haɗa su ba.Hakanan ya cancanci zanen waya don ƙarfe da ƙarfe mara ƙarfe, injin lantarki don amfani da ƙasa da rawar ƙarfe da sauransu. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Cancanta don sarrafa mashin ƙarfe na simintin ƙarfe, ƙarfe mara ƙarfe, kayan da ba na ƙarfe ba, zanen ƙarfe, ƙarfe mara ƙarfe da bututu, drills daban-daban don amfanin ƙasa, kayan aikin kera na'ura da sa sassa. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Cancanta don ƙarancin saurin injuna, milling alloy titanium da gami da jujjuyawa, musamman don kayan aikin yanke da siliki. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Wanda ya cancanci yin gyare-gyaren ƙwanƙwasa don rawar dutse mai nauyi: abubuwan da za a iya cirewa da ake amfani da su don hako rami mai zurfi, trolley rock da sauransu. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Cancanta don hakowa mai wuyar dutse, sandunan ƙarfe tare da ƙimar matsawa mai girma, zanen bututu, kayan aikin naushi, core majalisar na foda metallurgy atomatik molders da dai sauransu. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Cancanta don yin mutuwa tare da ƙaramin tasiri kamar naushi sassan agogo, harsashi na baturi, ƙananan madaukai da sauransu. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Cancantar yin gyare-gyaren taken sanyi, tambarin sanyi da latsa sanyi da ake amfani da shi don kera daidaitattun sassa, bearings da sauransu. | |

Teburin girma

| Model No. | Ƙayyadaddun bayanai | OD(D:mm) | ID (D1:mm) | Pore(d:mm) | Tsawon (L:mm) | Tsawon mataki (L1:mm) |

| KD-2001 | 01 | 16.41 | 14.05 | 12.70 | 25.40 | 1.00 |

| KD-2002 | 02 | 16.41 | 14.05 | 12.70 | 31.75 | 1.00 |

| KD-2003 | 03 | 22.04 | 18.86 | 15.75 | 31.75 | 3.18 |

| KD-2004 | 04 | 22.04 | 18.86 | 15.75 | 50.80 | 3.18 |

| KD-2005 | 05 | 16.00 | 13.90 | 10.31 | 76.20 | 3.18 |

| KD-2006 | 06 | 22.00 | 18.88 | 14.30 | 25.40 | 3.18 |

| KD-2007 | 07 | 24.00 | 21.00 | 16.00 | 75.00 | 3.00 |

| KD-2008 | 08 | 22.90 | 21.00 | 15.00 | 75.00 | 3.00 |

| KD-2009 | 09 | 19.50 | 16.90 | 12.70 | 50.00 | 4.00 |

| KD-2010 | 10 | 36.80 | 32.80 | 26.00 | 55.00 | 4.00 |