Sanin bakin karfe gama gari

Karfe kalma ce ta gaba ɗaya don gami da ƙarfe-carbon gami da abun cikin carbon tsakanin 0.02% da 2.11%.Fiye da 2.11% shine ƙarfe.

Abubuwan sinadaran karfe na iya bambanta sosai.Karfe mai dauke da carbon kawai ana kiransa karfen carbon ko karfe na yau da kullun.A cikin aikin narkewar ƙarfe, chromium, nickel, manganese, silicon, titanium, molybdenum da sauran abubuwan gami kuma ana iya ƙarawa don haɓaka kaddarorin ƙarfe.

Bakin karfe karfe ne wanda ke da mahimman halayen juriya na tsatsa da juriya na lalata, kuma abun ciki na chromium shine aƙalla 10.5%, kuma abun cikin carbon ɗin bai wuce 1.2% ba.

1. Bakin karfe ba zai yi tsatsa ba?

Lokacin da akwai wuraren tsatsa masu launin ruwan kasa (tabo) a saman bakin karfe, mutane suna mamaki.Suna tsammanin cewa bakin karfe ba zai yi tsatsa ba.Tsatsa ba bakin karfe bane.Yana iya zama saboda matsalar ingancin karfe.A gaskiya ma, wannan ra'ayi ne mara kyau na gefe ɗaya na rashin fahimtar bakin karfe.Bakin karfe zai yi tsatsa a ƙarƙashin wasu yanayi.Bakin karfe yana da ikon yin tsayayya da iskar iska mai iska - tsatsa juriya, kuma yana da ikon yin tsayayya da lalata a cikin matsakaici mai dauke da acid, alkali da gishiri, wato, juriya na lalata.Koyaya, juriyar lalata ta bambanta da sinadarai, yanayin juna, yanayin sabis da nau'in kafofin watsa labarai na muhalli.Misali, abu 304 yana da cikakkiyar juriya na lalata a bushe da tsaftataccen yanayi, amma idan aka koma bakin teku, nan da nan zai yi tsatsa a cikin hazon teku mai dauke da gishiri mai yawa.Saboda haka, ba kowane irin bakin karfe ba ne zai iya tsayayya da lalata da tsatsa a kowane lokaci.Bakin karfe siriri ne, mai ƙarfi kuma lafiyayyan barga mai arzikin oxide na chromium (fim ɗin kariya) da aka kafa akan samansa don hana atom ɗin oxygen ci gaba da shiga da oxidize, don haka samun ikon jure lalata.Da zarar saboda wasu dalilai, fim din ya ci gaba da lalacewa, atom ɗin oxygen da ke cikin iska ko ruwa za su ci gaba da shiga ko kuma atom ɗin ƙarfen da ke cikin ƙarfe zai ci gaba da rabuwa, ya haifar da sako-sako da ƙarfe, kuma saman karfen zai kasance yana lalacewa.

2. Wani irin bakin karfe ne ba sauki ga tsatsa?

Akwai manyan abubuwa guda uku da suka shafi lalata bakin karfe.

1) Abun ciki na alloying abubuwa

Gabaɗaya magana, ƙarfe tare da abun ciki na chromium 10.5% ba shi da sauƙin tsatsa.Mafi girman abun ciki na chromium da nickel, mafi kyawun juriya na lalata.Misali, abun ciki na nickel abu 304 shine 8% ~ 10%, kuma abun ciki na chromium shine 18% ~ 20%.Irin wannan bakin karfe ba zai yi tsatsa a karkashin yanayi na al'ada ba.

2) Tsarin narkewar masana'antar samarwa

Tsarin narkewar masana'antar samarwa kuma zai shafi juriyar lalata na bakin karfe.Manyan shuke-shuken bakin karfe tare da fasaha mai kyau na narkewa, kayan aiki na ci gaba da fasaha na ci gaba ana iya tabbatar da su dangane da sarrafa abubuwan haɗaka, kawar da ƙazanta, da kula da yanayin sanyi na billet.Sabili da haka, ingancin samfurin yana da kwanciyar hankali kuma abin dogara, ingancin ciki yana da kyau, kuma ba shi da sauƙi ga tsatsa.Akasin haka, wasu ƙananan masana'antun ƙarfe suna da baya a cikin kayan aiki da fasaha.A lokacin aikin narkewa, ba za a iya cire ƙazanta ba, kuma samfuran da aka samar za su yi tsatsa ba makawa.

3) muhallin waje

Yanayin tare da busassun yanayi da kuma samun iska mai kyau ba sauki ga tsatsa ba.Duk da haka, wuraren da ke da matsanancin zafi na iska, ci gaba da yanayin damina, ko yawan acidity da alkalinity a cikin iska suna da haɗari ga tsatsa.304 bakin karfe zai yi tsatsa idan yanayin da ke kewaye ya yi rauni sosai.

3. Yadda za a magance m spots a kan bakin karfe?

1) Hanyoyin sinadarai

Yi amfani da man goge acid ko fesa don taimakawa sassan da suka lalace don sake yin fim ɗin chromium oxide don dawo da juriyar lalatarsu.Bayan tsaftacewa na acid, don kawar da duk abubuwan da ba su da kyau da kuma ragowar acid, yana da matukar muhimmanci a wanke da kyau tare da ruwa mai tsabta.Bayan duk jiyya, sake gogewa tare da kayan aikin gogewa kuma hatimi tare da kakin zuma mai gogewa.Don sassan da ke da ƙananan tsatsa, 1: 1 petur da cakuda man inji kuma za a iya amfani da su don shafe tsatsa da tsatsa.

2) Hanyar injina

Tsabtace fashewar fashewar fashewar fashewar fashewar bam, harbin iska tare da gilashin ko yumbu, lalatawa, gogewa da goge goge.Yana yiwuwa a share gurɓatar da kayan da aka cire a baya, kayan goge-goge ko kayan da aka lalata su ke haifarwa ta hanyoyin inji.Duk nau'ikan gurɓataccen yanayi, musamman ma baƙin ƙarfe na waje, na iya zama tushen lalata, musamman a cikin yanayi mai ɗanɗano.Sabili da haka, ya kamata a tsabtace farfajiyar da aka tsabtace ta inji a ƙarƙashin bushewa.Yin amfani da hanyar inji kawai zai iya tsaftace samansa kuma ba zai iya canza juriyar lalata kayan da kanta ba.Sabili da haka, ana ba da shawarar sake gogewa tare da kayan aikin gogewa bayan tsaftacewa na injiniya, da hatimi tare da kakin zuma.

4. Za a iya yin hukunci da bakin karfe ta hanyar maganadisu?

Mutane da yawa suna zuwa siyan kayan bakin karfe ko bakin karfe suna kawo karamin maganadisu.Idan suka kalli kayan sai su dauka cewa bakin karfe mai kyau shi ne wanda ba zai iya shanyewa ba.Idan babu maganadisu, ba za a sami tsatsa ba.A gaskiya, wannan rashin fahimta ce.

Ƙaƙwalwar bakin karfe ba na maganadisu ba an ƙaddara ta tsarin.A lokacin da ƙarfi tsari na narkakkar karfe, saboda daban-daban solidification zafin jiki, shi zai samar da bakin karfe da daban-daban tsarin kamar "ferrite", "austenite" da "martensite", daga cikinsu akwai "ferrite" da "martensite" bakin karfe ne Magnetic karfe. .Bakin karfe na "austenitic" yana da kyawawan kaddarorin inji da kuma walƙiya, amma bakin karfe "ferritic" tare da magnetism ya fi ƙarfin "austenitic" bakin karfe kawai dangane da juriya na lalata.

A halin yanzu, abin da ake kira jerin 200 da jerin bakin karfe 300 masu dauke da sinadarin manganese da karancin sinadarin nickel a kasuwa su ma ba su da maganadisu, amma aikinsu ya yi nisa da na 304 tare da babban abun ciki na nickel.Sabanin haka, 304 kuma za su sami micro-magnetism bayan shimfidawa, annealing, gogewa, simintin gyare-gyare da sauran matakai.Don haka, rashin fahimta ne da rashin kimiyya a yi la'akari da fa'ida da rashin amfani da bakin karfe ta amfani da bakin karfe ba tare da maganadisu ba.

5. Menene nau'ikan nau'ikan bakin karfe da aka saba amfani da su?

201: Ana amfani da manganese maimakon nickel bakin karfe, wanda ke da wasu acid da juriya na alkali, babban yawa, gogewa kuma babu kumfa.Ana amfani da shi don kallon lokuta, bututun ado, bututun masana'antu da sauran samfuran da aka zana marasa zurfi.

202: Nasa ne na ƙaramin nickel da babban bakin ƙarfe na manganese, tare da abun ciki na nickel da manganese kusan 8%.A karkashin raunin lalata yanayi, zai iya maye gurbin 304, tare da babban farashi.An fi amfani da shi a cikin kayan ado na gine-gine, shingen tsaro na babbar hanya, injiniya na birni, gilashin hannu, kayan aiki na mota, da dai sauransu.

304: Gabaɗaya bakin karfe, tare da juriya mai kyau, juriya mai zafi, ƙarancin zafin jiki da kaddarorin inji, da ƙarfin ƙarfi, ana amfani dashi a cikin masana'antar abinci, masana'antar likitanci, masana'antu, masana'antar sinadarai, da masana'antar kayan ado na gida.

304L: low carbon 304 bakin karfe, amfani da kayan aiki sassa tare da lalata juriya da formability.

316: Tare da ƙari na Mo, yana da kyakkyawan juriya na lalata yanayin zafi kuma ana amfani dashi a cikin filayen kayan aikin ruwa, sunadarai, masana'antar abinci da yin takarda.

321: Yana da kyakkyawan yanayin damuwa mai ƙarfi da ƙarfin juriya mai zafi.

430: gajiya mai jurewa zafi, ƙimar haɓakar thermal faɗaɗa ƙasa ta fi na austenite, kuma ana amfani da ita ga kayan aikin gida da kayan ado na gine-gine.

410: Yana da babban taurin, tauri, mai kyau juriya na lalata, babban haɓakar thermal, ƙaramin haɓaka haɓakawa, da ingantaccen juriya na iskar shaka.Ana amfani da shi don kera yanayi, tururin ruwa, ruwa da sassan lalata acid oxidizing.

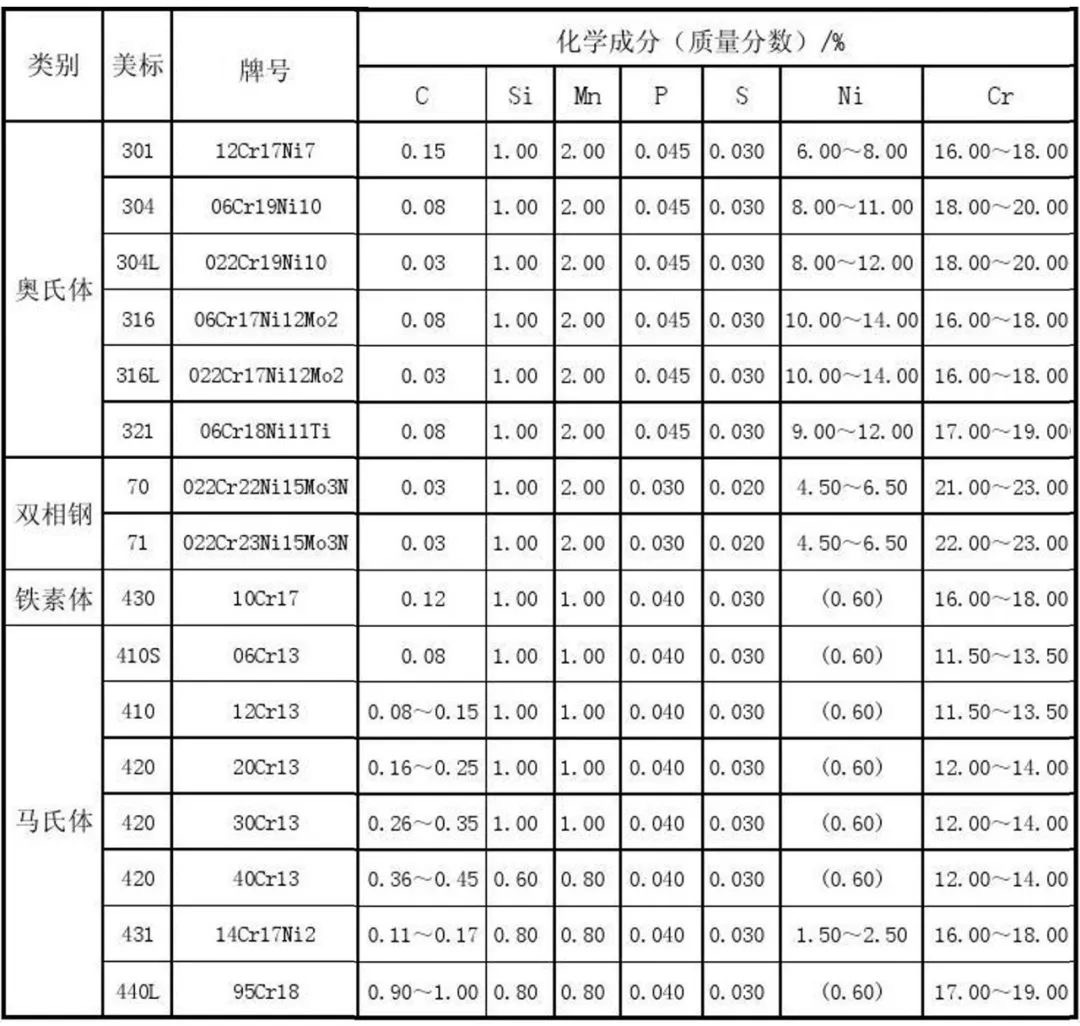

Mai zuwa shine teburin abun ciki na “haɓaka gami” na nau'ikan ƙarfe daban-daban na bakin karfe na gama gari don tunani kawai:

Lokacin aikawa: Janairu-30-2023